The world of glass handling has undergone a remarkable transformation, thanks to the invention of glass vacuum lifters. These ingenious devices have their roots in the mid-20th century when the demand for safer and more efficient methods of moving large glass panes surged. Before their development, handling glass was a risky endeavor that relied heavily on brute strength, risking breakage and injury.

Early vacuum lifters were a game-changer. They used basic suction technology to create a secure grip on glass surfaces, drastically reducing the need for manual labor and minimizing the danger of accidents. These early models were relatively simple but laid the groundwork for the sophisticated lifters we see today.

Fast forward to the present, and glass vacuum lifters have evolved into high-tech marvels. Modern lifters boast powerful suction mechanisms, computerized controls, and advanced safety features, making them essential tools in construction, manufacturing, and beyond. Whether installing massive glass facades on skyscrapers or delicately placing glass in automotive assemblies, these lifters provide unmatched precision and safety.

Looking ahead, the future of glass vacuum lifters promises even more innovation. With advancements in artificial intelligence and robotics on the horizon, these tools will continue to push the boundaries of what’s possible in glass handling.

What Are Glass Manipulators?

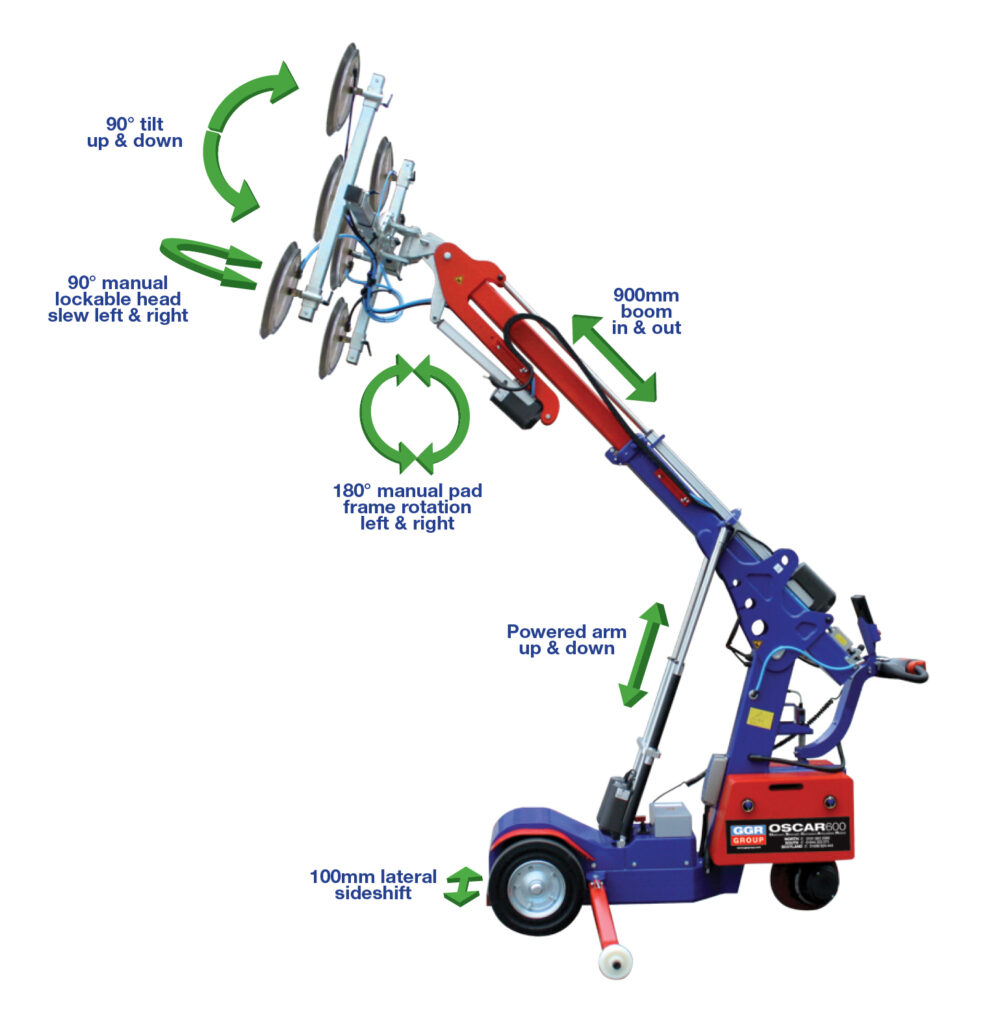

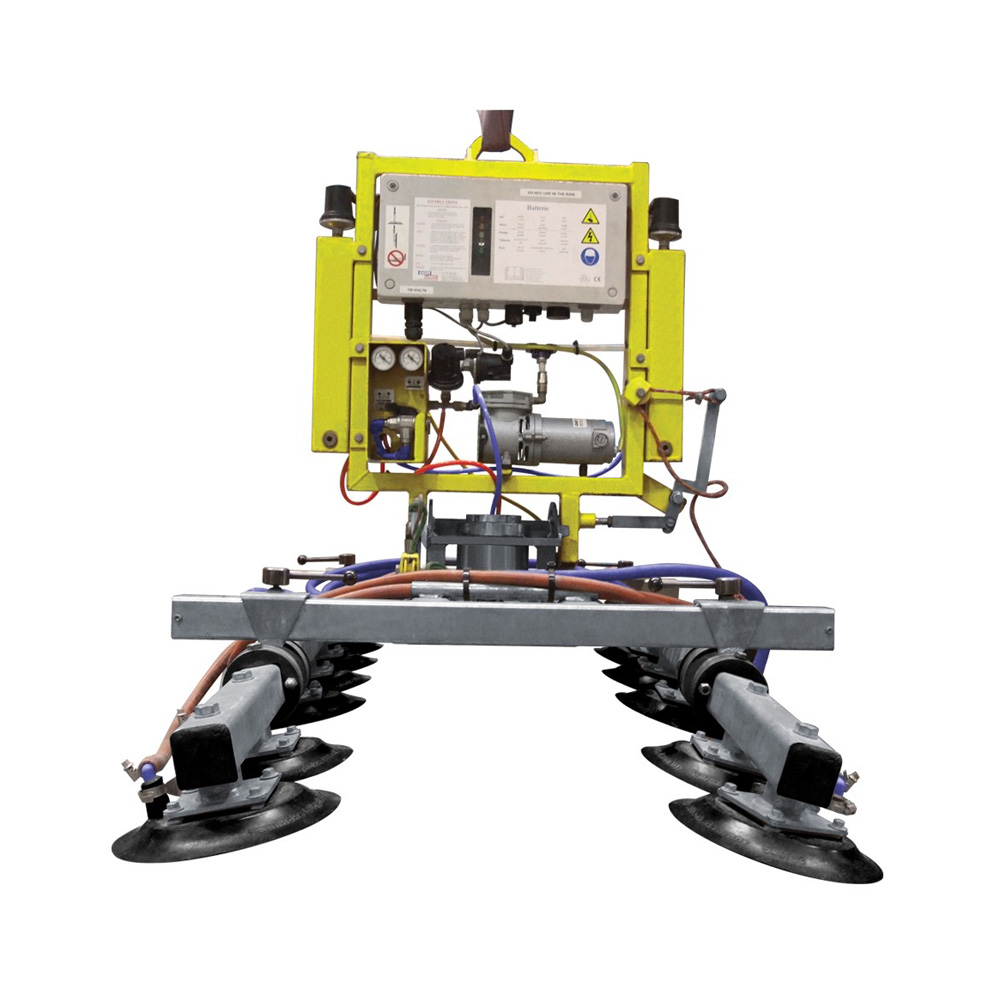

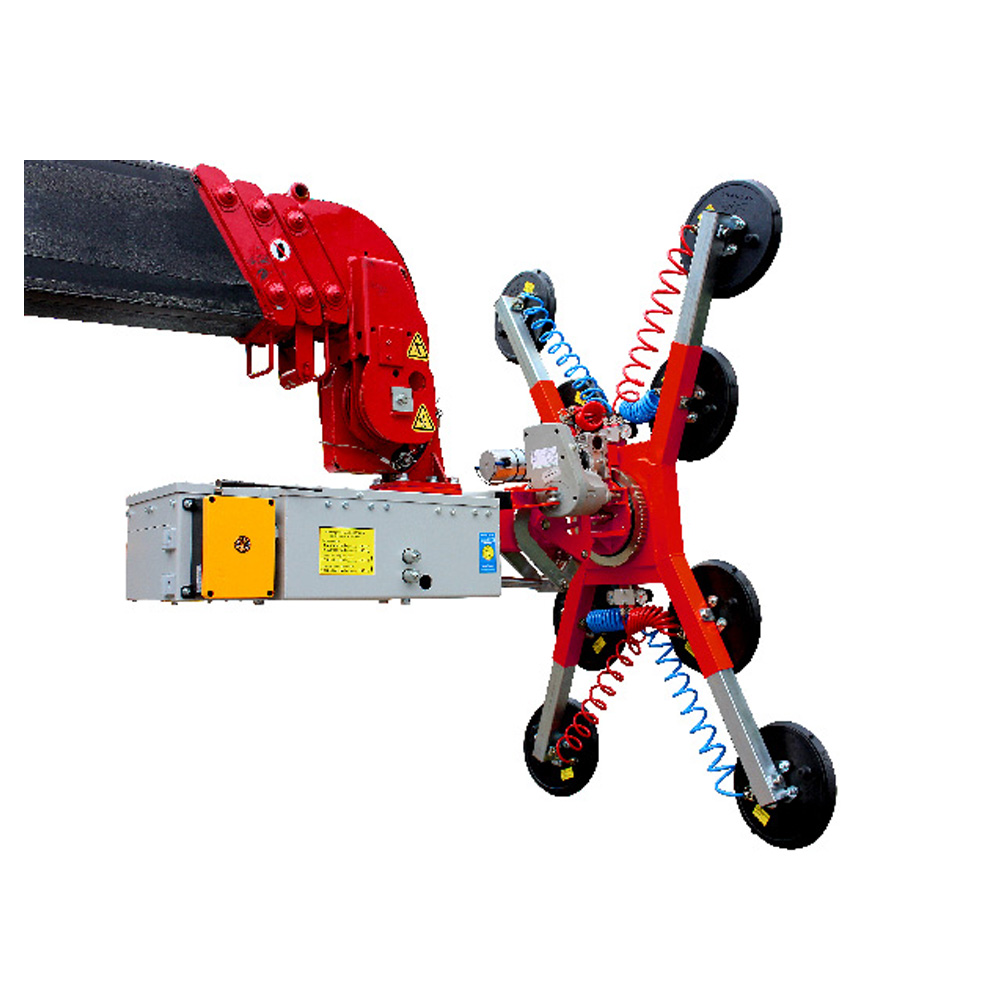

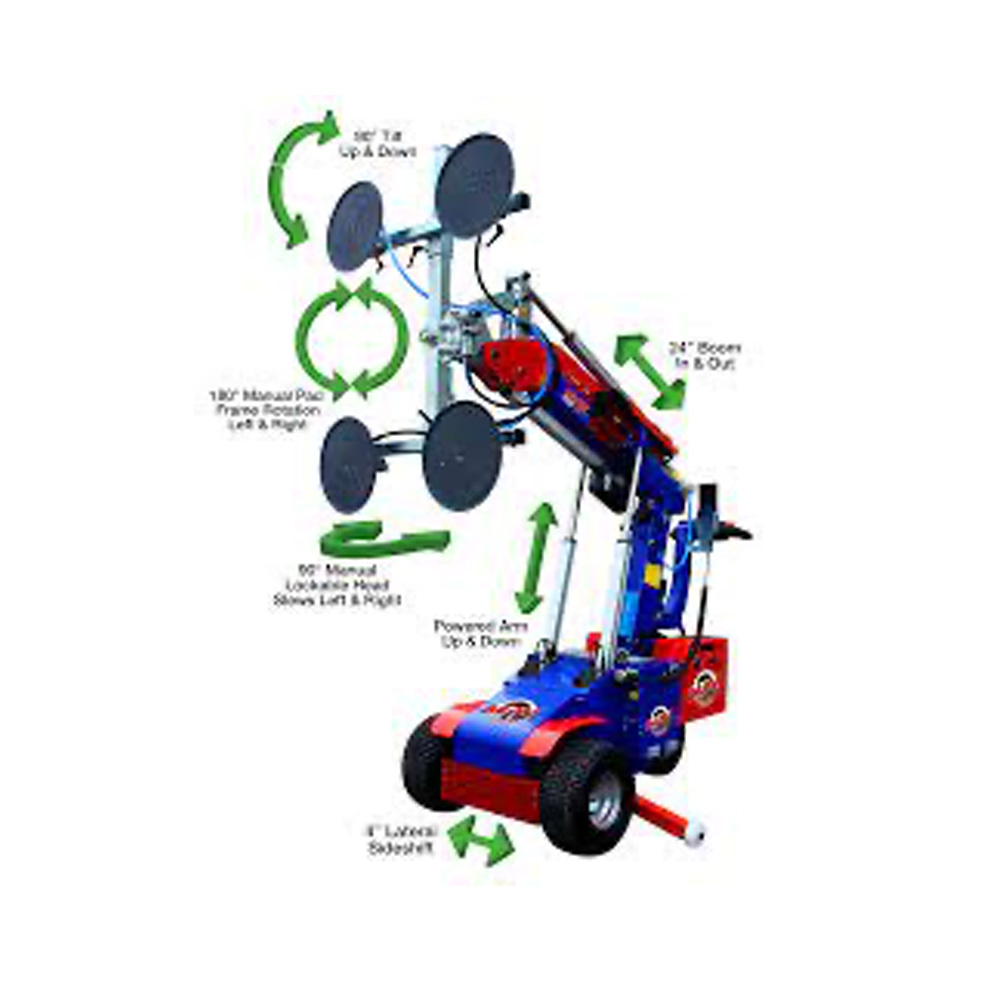

Glass manipulators come in various designs and are equipped with different mechanisms like vacuum suction cups, robotic arms, and hydraulic systems to grip and move glass panes securely. They are often used to lift, tilt, rotate, and position glass panels accurately, reducing the risk of damage or injury during the process. These devices are particularly useful for handling large, heavy, or fragile glass sheets that are difficult to manage manually.

Benefits of Using Glass Manipulators

Glass manipulators are invaluable in today’s industries, offering a combination of safety, efficiency, and precision that manual handling simply can’t match. As technology continues to advance, these devices are likely to become even more versatile and integral to glass handling processes across various sectors.

The Key differences between a Vacuum Glass Lifter and a manipulator

The best way to explain the difference between the two is that vacuum glass lifters are generally used for installations where the glass is lowered from above and manipulators are generally used where glass needs to be installed from below or where there is not the possibility to lower a vacuum lifter from above (like a crane hook)

Manipulator

Attachment Method:

Contact us for more details on professional lifting solutions.

(Spider Plus Construction Equipment Trading LLC https://www.spiderplus.ae/) we have a great range of spider cranes, vacuum glass lifter, whatever your requirement is, get in touch with our team today and we our team will be happy to assist you on the right options. enquiries@spiderplus.ae

Warehouse 17, Alserkal Complex Dubai Investment Park 1, Dubai, UAE

EXIT 17, Haroun Al Rasheed St. RIYADH, KSA

© 2026 Spider Plus